Heat shrink that

holds up in the field.

Heat shrink that

holds up in the field.

3M heat shrink tubing delivers professional-grade insulation and moisture protection for electrical connections from low-voltage control work to high-voltage splicing up to 35kV. Available in single-wall, dual-wall, and heavy-wall configurations, 3M tubing provides the exact shrink ratio and voltage rating you need while meeting UL, CSA, and MIL-spec standards. When connections matter, contractors choose 3M for consistent shrinkage and long-term reliability.

Summit Electric Supply stocks the complete range of 3M heat shrink solutions. From terminal protection to underground splicing, we help you match the right tubing to your cable type, environment, and installation requirements—with local availability and same-day fulfillment.

Navigate 3M Heat Shrink Tubing:

What you can expect from 3M Heat Shrink Tubing.

What you can expect from 3M Heat Shrink Tubing.

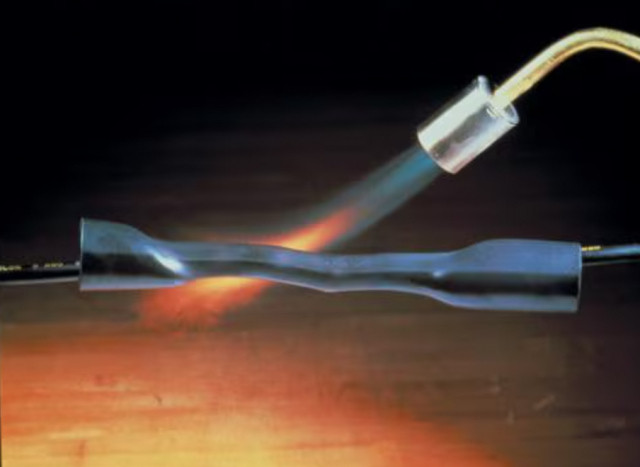

- Insulation Repair – Covers exposed conductors at splices, terminals, or cutbacks to help prevent arcing and restore electrical integrity.

- Moisture Sealing – Adhesive-lined tubing bonds to cable jackets and terminals to block water and corrosion from penetrating the connection point.

- Voltage Range Coverage – Available in low- and high-voltage options so crews can match the right product to the job without compromise.

- Fast Application – Shrinks quickly and uniformly using standard heat tools for a secure, professional result that holds tight over time.

- Secure Fit – Maintains grip and form even under vibration, movement, or thermal cycling in demanding industrial or outdoor settings.

- Environmental Resistance – Select tubing withstands abrasion, fuels, solvents, and high heat for long-term protection in harsh environments.

- Standards Compliant – Meets UL, CSA, and often MIL-spec standards to support reliable, code-compliant installations.

Featured 3M Heat Shrink Tubing Products

Featured 3M Heat Shrink Tubing Products

Single Wall Tubing

Simple insulation for clean, professional wire terminations.

Single Wall Tubing

Simple insulation for clean, professional wire terminations.

Includes: FP-301, FP-301VW, VTN Series

- Used for wire marking, strain relief, and light-duty bundling in control panels and harnesses

- Flexible and flame-retardant for indoor or OEM use

- Available in multiple shrink ratios and diameters for applications up to 600 V

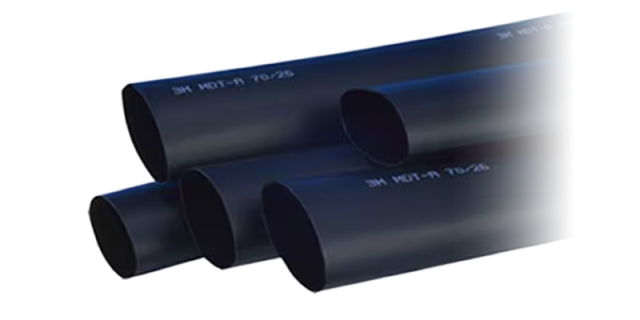

Dual Wall Tubing | Adhesive-Lined

Seals out moisture while protecting the connection underneath.

Dual Wall Tubing | Adhesive-Lined

Seals out moisture while protecting the connection underneath.

Includes: EPS, MDT, HDT-AN Series

- Adhesive lining bonds to cable jackets and terminals to create a watertight seal

- Ideal for splices, connectors, or jacket repairs in wet or harsh environments

- Commonly used in automotive, marine, industrial, and field wiring

Medium & Heavy Wall Tubing

Extra protection for buried or high-abuse cable work.

Medium & Heavy Wall Tubing

Extra protection for buried or high-abuse cable work.

Includes: ITCSN, HDT, HDCW Series

- Rated for insulation and sealing of cables from 600 V up to 1 kV with specialized applications to 35 kV for jacket repair

- Thick wall tubing provides abrasion and impact resistance

- Adhesive-lined variants support direct burial and conduit entry

High-Voltage Tubing

Built for critical splices and terminations in power systems.

High-Voltage Tubing

Built for critical splices and terminations in power systems.

Includes: BBI, HDCW Series

- Provides electrical insulation and stress control up to 35 kV

- Used in switchgear, transformer feeds, and primary feeders

- Designed to withstand heat, tracking, and long-term aging

Special Use Tubing

Designed for environments where standard tubing falls short.

Special Use Tubing

Designed for environments where standard tubing falls short.

Includes: 3M™ CGAT, 3M™ SFTW, 3M™ VFP Series.

- Offers resistance to fuels, solvents, and elevated temperatures

- Options available for ID marking, printable sleeves, or clear inspection tubing

- Used in aerospace, military, and engine bay environments